- Why is hydrogen becoming so important in the energy transition?

- How can digital planning accelerate hydrogen projects?

- Why is standardization essential for long-term efficiency?

- How can modular concepts enable global scaling?

- How do digital tools improve hydrogen plant projects?

- Why is mobility crucial in project execution?

- What new standards are emerging in low-voltage planning?

Why is hydrogen becoming so important in the energy transition?

The world is increasingly shifting toward renewable energy and diversifying its energy sources. This shift also impacts the oil and gas industry, which must adapt to more sustainable energy forms. Hydrogen is emerging as one of the most promising alternatives – as an energy carrier, fuel, and a key pillar of global decarbonization.

The energy transition needs pace-setters. Rapid transformation of energy systems requires time- and cost-saving value chains across all sectors – along with standardized, proven system solutions and digital planning methods.

How can digital planning accelerate hydrogen projects?

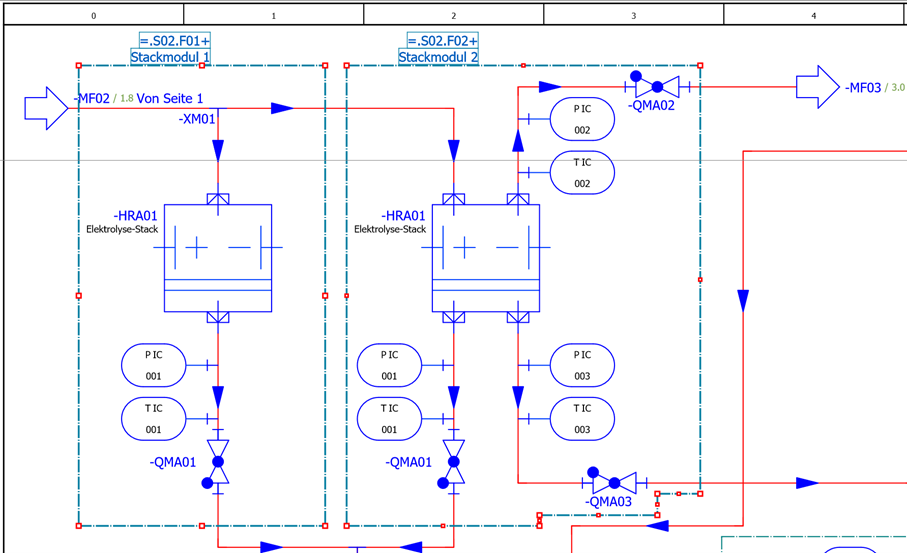

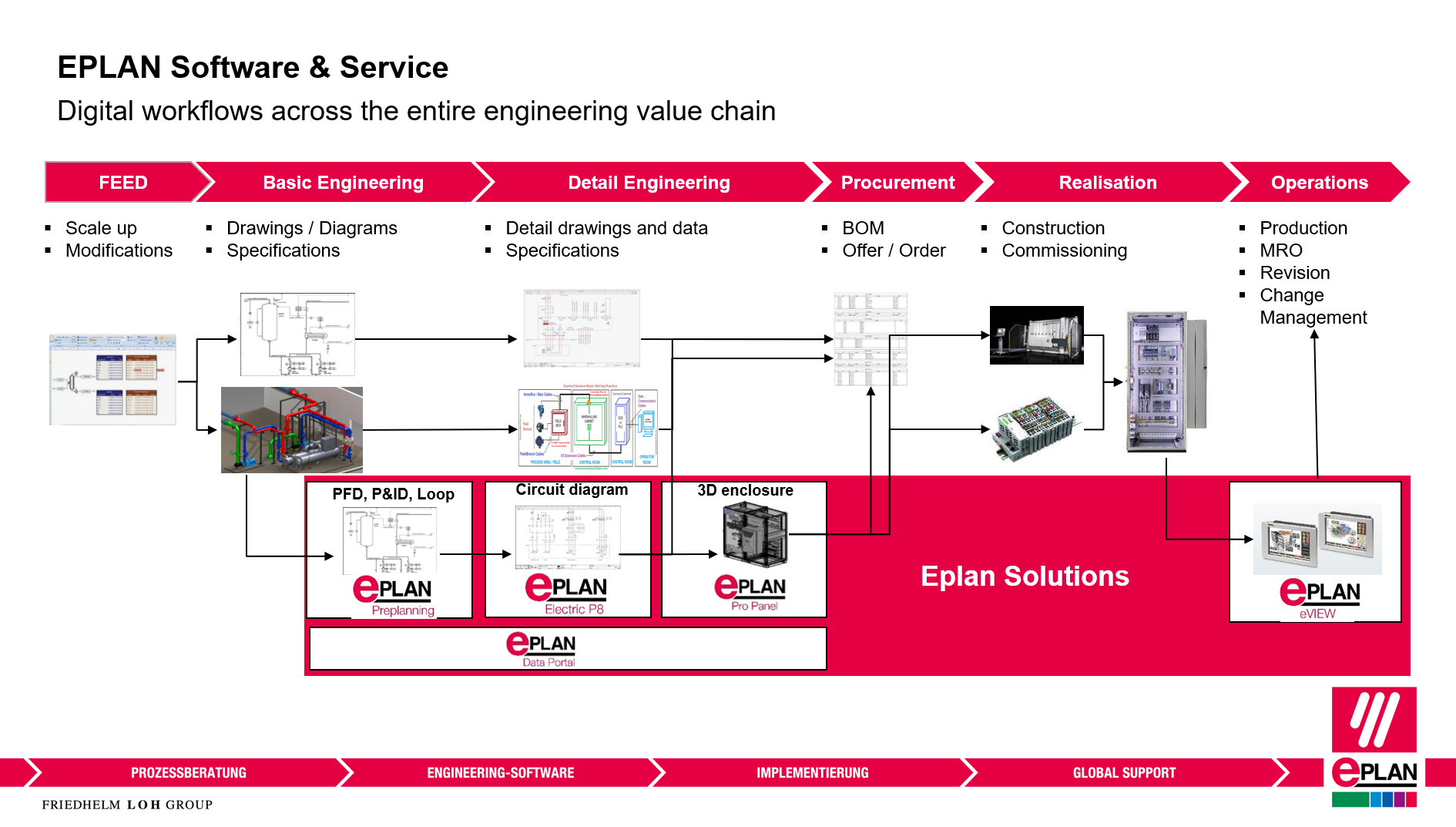

Whether for large international projects or smaller installations ranging from 1 to 5 MW, plant operators and system integrators benefit from seamless digital engineering solutions that cover the entire lifecycle of hydrogen systems – from initial planning through operation to maintenance.

Standard-compliant, multilingual documentation, open interfaces, and up-to-date digital twins provide transparency and high system availability. These elements ensure full control – from the early FEED phase to day-to-day operations.

Digital platforms and centralized data models simplify project workflows, accelerate commissioning, and ease future modifications.

Why is standardization essential for long-term efficiency?

Long-term success in the hydrogen economy requires efficiency, flexibility, and scalability. Comprehensive engineering strategies based on structured data models and standardized workflows enable consistent planning – from process engineering to control cabinet design.

Cross-disciplinary integration, automated workflows, and seamless interaction with existing IT systems (such as ERP or PDM) increase efficiency across the entire value chain.

Standardized systems in power distribution, plant design, and industrial climate control offer further advantages in safety, maintainability, and global usability.

How can modular concepts enable global scaling?

Standardized products and processes – available globally with consistent quality – are key to saving time and cost in hydrogen projects.

Modular system designs, with Standardized enclosures, power distribution components and cooling solutions based on water or air cooling enabled, allow complex projects to be divided into manageable, clearly defined segments. This enhances transparency and enables the repeatable use of proven solutions for specific tasks – regardless of location.

How do digital tools improve hydrogen plant projects?

Modern engineering tools allow hydrogen-related components to be integrated directly into project planning – with real-time data and technical specifications. This not only speeds up procurement but creates a consistent digital representation of the entire plant.

Changes during the project can be fully documented and tracked at any time. The digital project documentation can also serve as a foundation for operations and maintenance – accessible anywhere, anytime.

Why is mobility crucial in project execution?

Mobility is a critical success factor in today’s project execution. Modern digital solutions provide access to project statuses, documentation, and schematics – independent of location and in real time.

Online tools for documentation and cross-disciplinary collaboration streamline decision-making – for example, in maintaining switchgear systems or managing updates to individual components.

What new standards are emerging in low-voltage planning?

Cloud-based solutions are also establishing themselves in low-voltage power distribution. They guide planners through the entire process – from system design to documentation – in logical, transparent steps. The focus is on efficiency, compliance, and planning confidence.

Especially in the hydrogen sector, where projects often involve tight timelines and strict safety standards, these tools offer significant advantages.

Content contributed by Rittal GmbH & Co. KG

Rittal is a leading global supplier of enclosure systems, automation and infrastructure with the divisions Industry, IT, Energy & Power, Cooling and Service. Rittal products and solutions are used in over 90 per cent of industries worldwide – standardised, customised, in the best quality.

Eplan offers software and services for engineering in the fields of process automation, electrical engineering and automation. The company develops one of the world's leading software solutions for mechanical, plant and panel building. Eplan is also the ideal partner for simplifying challenging engineering processes. Our approach: Combining hardware and software expertise, Rittal, Rittal Software Systems (Eplan, Cideon) and Rittal Automation Systems (RAS, Ehrt, Alfra) optimise, digitise and automate their customers' processes along the entire value chain, including the IT infrastructure – from panel building and mechanical engineering to the manufacturing industry and the energy sector. The companies belong to the owner-managed Friedhelm Loh Group, which employs 12,100 people and generated a turnover of 3 billion euros in 2023.