- What makes stainless steel tubes indispensable for safe hydrogen applications?

- How do material selection and precision affect the service life of stainless steel tubes in hydrogen operation?

- How do compression fittings contribute to the future of hydrogen technology?

- Why does the choice of raw material determine the safety of a hydrogen system?

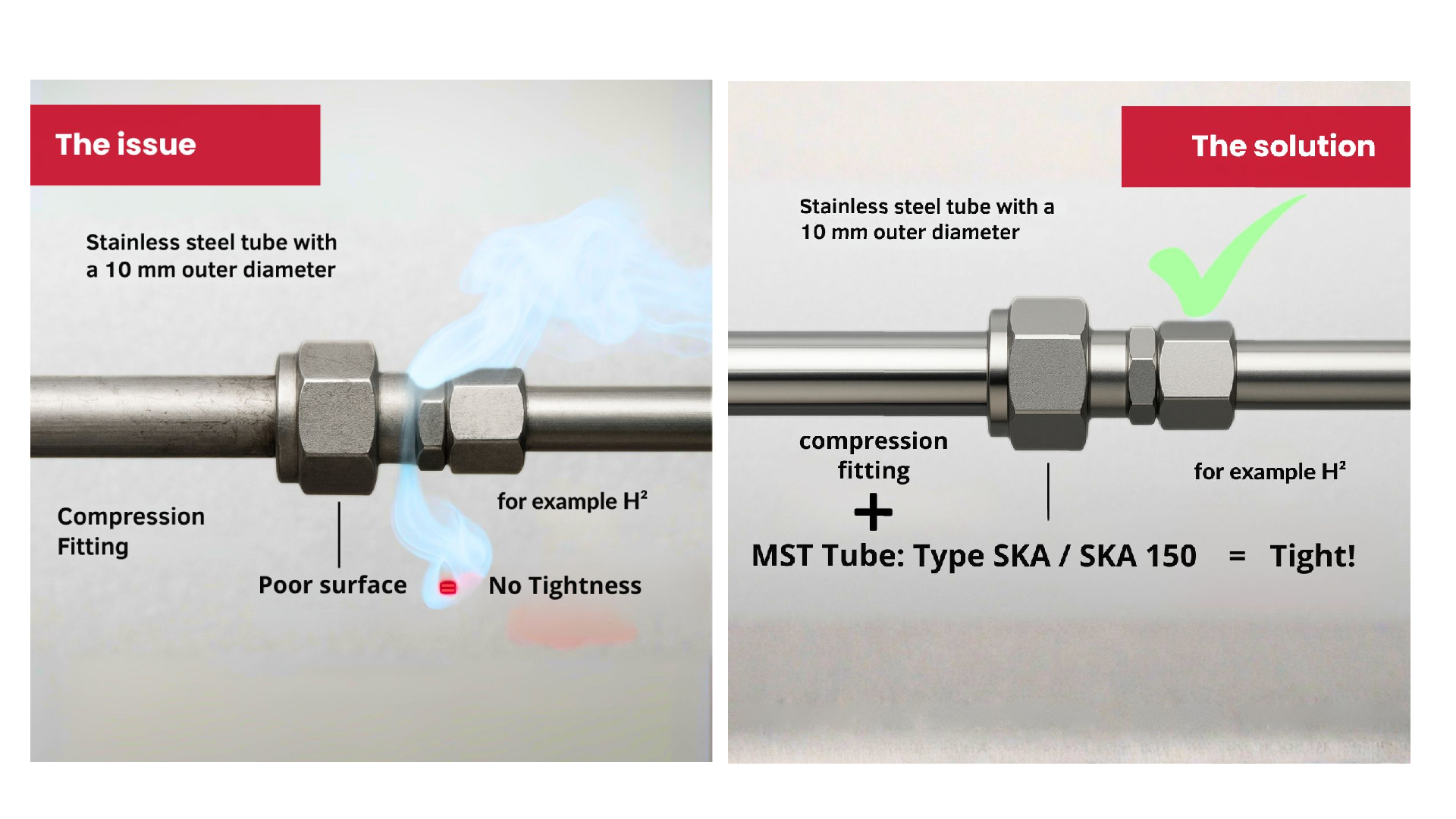

- Can specially manufactured stainless steel tubes combined with precision compression fittings make the difference between tightness and leakage?

- What role do stainless steel tubes play in linking innovation and safety in the hydrogen sector?

- How do modern compression fittings enhance efficiency in sensitive hydrogen applications?

- What distinguishes compression fitting solutions for hydrogen systems from conventional tube connections?

- Why are leak-tightness and material quality so critical in compression fittings?

What makes stainless steel tubes indispensable for safe hydrogen applications?

Stainless steel tubes are exceptionally resistant to corrosion, pressure, and high temperatures, making them ideal for hydrogen applications. They effectively prevent chemical reactions between hydrogen and the tube material that could lead to embrittlement or leaks. High-quality stainless steel tubes ensure a clean and controlled flow of hydrogen without contamination. Their mechanical stability guarantees long-term safety of the system. Thus, stainless steel tubes are a key factor in the efficiency and reliability of modern hydrogen systems.

How do material selection and precision affect the service life of stainless steel tubes in hydrogen operation?

High-grade materials with low hydrogen embrittlement are crucial for ensuring long service life of the tubes. Precisely manufactured stainless steel tubes prevent microcracks and leaks, even under high pressure. The combination of suitable material and accurate production increases the durability of the entire hydrogen installation. At the same time, it minimises maintenance costs and ensures continuous operational safety. Material selection and precision are therefore central factors in achieving long-lasting hydrogen systems.

How do compression fittings contribute to the future of hydrogen technology?

Compression fittings provide a flexible and secure connection between tubes without the need for welding. They ensure reliable sealing even under high pressures and temperature fluctuations in hydrogen applications. Precisely machined fittings minimise the risk of leakage, significantly enhancing operational safety. In addition, they simplify the installation, maintenance, and modification of tube systems. Compression fittings thus play a vital role in the sustainable advancement of modern hydrogen infrastructure. A stainless steel tube suitable for compression fittings is absolutely essential.

Why does the choice of raw material determine the safety of a hydrogen system?

The raw material defines the resistance to hydrogen embrittlement, corrosion, and mechanical stress. Stainless steel and special alloys have proven particularly suitable, as they remain chemically stable and prevent microcracking. The choice of material directly influences the service life and operational safety of hydrogen tubing. High-quality materials reduce maintenance requirements and minimise the risk of unexpected failures. In sensitive hydrogen applications, material selection is therefore crucial for the safety of the entire system.

Can specially manufactured stainless steel tubes combined with precision compression fittings make the difference between tightness and leakage?

Yes, manufacturing precision is critical for secure sealing. Accurately produced stainless steel tubes and compression fittings create uniform surface pressure, preventing microleakages. This is especially important in hydrogen applications, where even small leaks pose significant risks. This coordinated system of precision tube and compression fittings also simplifies installation and maintenance. Their quality thus directly contributes to the operational safety and efficiency of tube systems.

What role do stainless steel tubes play in linking innovation and safety in the hydrogen sector?

Stainless steel tubes combine chemical resistance with mechanical stability, enabling innovative hydrogen applications. They are suitable for high-pressure and high-temperature systems and can be flexibly integrated into modern setups. Their versatility allows new technologies to be tested without compromising operational safety. Stainless steel tubes therefore unite technical innovation with practical reliability.

How do modern compression fittings enhance efficiency in sensitive hydrogen applications?

Modern compression fittings significantly reduce installation time, as they can be assembled without welding. They allow quick adjustments or extensions of tube systems, which is especially valuable in dynamic hydrogen projects. Furthermore, they are easy to disassemble and reuse, lowering maintenance costs. Overall, compression fittings increase efficiency, safety, and flexibility in hydrogen installations.

What distinguishes compression fitting solutions for hydrogen systems from conventional tube connections?

Compression fitting solutions for hydrogen systems are specifically designed for high sealing requirements, precision, and suitable materials. They withstand high pressures and maintain hydrogen purity without leakage. Conventional methods, such as welding tubes, often cannot offer the same level of safety and flexibility. Compression fitting solutions enable modular adjustments, easy maintenance, and repeated assembly. They thus combine safety, durability, and efficiency – essential qualities for modern hydrogen applications.

Why are leak-tightness and material quality so critical in compression fittings?

Leaks in hydrogen systems pose major safety risks, as hydrogen is highly flammable. High-quality stainless steel tubes and precisely machined compression fittings ensure secure sealing even under demanding operating conditions. They enhance operational safety and reduce failure risks, which is particularly important in sensitive installations. Leak-tightness extends the service life of tube systems and minimises maintenance requirements. Material quality and precise workmanship are therefore indispensable for efficient hydrogen applications.

Content contributed by MST Edelstahlrohr GmbH

MST Edelstahlrohr GmbH is a leading supplier of high-quality seamless stainless steel tubes and specialty alloys – and a reliable partner for companies in the hydrogen industry. Founded in 2010 and based in Ratingen (near Düsseldorf, Germany), MST supports hydrogen projects across Europe with precision tube solutions that meet the demanding standards of this forward-looking sector. In the development and operation of hydrogen systems – whether electrolyzers, fuel cell stacks, test benches, or hydrogen refueling stations – choosing the right tubing components is critical. This is where MST comes in: A large and diverse inventory, including stainless steels, duplex, super duplex, titanium, and nickel-based alloys, ensures a dependable supply – even for complex or urgent requirements. Beyond classic hydraulic and instrumentation tubing, MST also offers capillary tubes, high-pressure tubing, as well as specially cleaned and coated versions – ideal for use in H₂-compatible systems. With premium materials, precise processing, and customized services, MST is a key building block for any hydrogen application. Accessories like high-quality tubing systems are just as essential to hydrogen projects as the core technologies. Stainless steel tubes from MST are the perfect complement to any H₂ setup. Discover the MST Edelstahlrohr GmbH portfolio now – and take your hydrogen projects to the next level.